Microstructure Description

-

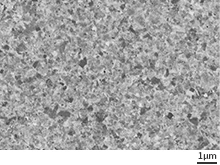

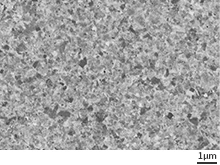

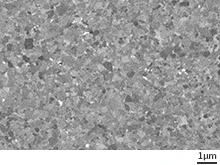

AF2003

AF2003

-

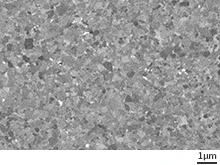

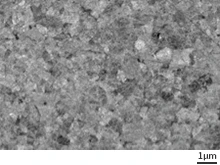

AF2005

AF2005

-

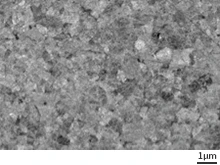

AF3005

AF3005

In order to improve the hardness of the alloy, it is necessary to reduce the cobalt content, which is binder metal, in addition to the decreasing the grain size of tungsten carbide. We have developed a carbide grade with significantly improved hardness by reducing the cobalt content of the binder metal while using ultra micro fine tungsten carbide, all while maintaining necessary overall strength.

High hardness is achieved by using high quality ultra-micro tungsten carbide and minimizing the amount of binder.

For details, please refer to the technical information.

AF2003

AF2003

AF2005

AF2005

AF3005

AF3005

| Binder content (wt%) |

Hardness HRA HV(GPa) |

|

|---|---|---|

| AF2003 | 0.3 | 27.5 |

| AF2005 | 0.5 | 27.0 |

| AF3005 | 0.5 | 25.3 |

For applications that require high wear resistance for abrasion resistant parts such as water jet nozzles.

By mixing an abrasive with a water jet, it is possible to cut hard materials. Other industries also include applications for ships and aircraft.

Please click here to inquire “Product Inquiries”.