Microstructure of Typical Grades

-

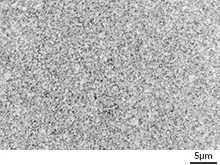

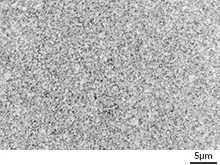

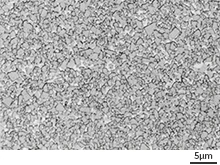

Ultra micro grainAF312

Ultra micro grainAF312

-

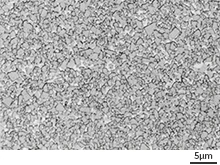

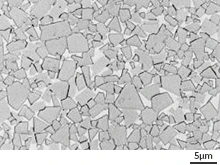

Medium grainAV212

Medium grainAV212

-

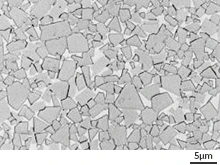

Coarse grainAG411

Coarse grainAG411

For wear-resistant tools and materials that require tough wear resistance. This product offering featuring coarse particles and a large amount of binder material is most applicable.

AV series is available for Wear resistant grade, and AG series is available for Impact resistant grade.

For details, please refer to the technical information.

Swipe left or right

to see.

| Application | Class | ISO code |

Grade | Hardness HRA | TRS | |

|---|---|---|---|---|---|---|

| HRA | Hv(GPa) | (GPa) | ||||

| For Wear & Impact resistant tools , parts | Wear resistance | --- | AV106 | 92.4 | 16.7 | 2.1 |

| --- | AV207 | 90.9 | 15.0 | 3.0 | ||

| --- | AV210 | 89.8 | 13.7 | 3.2 | ||

| --- | AV212 | 89.0 | 13.1 | 3.3 | ||

| --- | AV215 | 87.8 | 11.9 | 3.3 | ||

| --- | AV320 | 84.5 | 9.3 | 3.0 | ||

| --- | AV325 | 83.0 | 8.2 | 2.9 | ||

| Impact resistance | --- | AG408 | 89.0 | 12.9 | 2.8 | |

| --- | AG410 | 87.7 | 11.8 | 2.8 | ||

| --- | AG411 | 87.0 | 11.2 | 2.8 | ||

| --- | AG416 | 85.5 | 10.2 | 2.7 | ||

Ultra micro grainAF312

Ultra micro grainAF312

Medium grainAV212

Medium grainAV212

Coarse grainAG411

Coarse grainAG411

Swipe left or right

to see.

| Application | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Application | Class | ISO code |

Grade | Wear resistance | Slitter & Blade | Die & Mold | ||||||||

| Wear resistance | Impact resistance | General cutting | Metal cutting | Crushing | Press mold | Plastic injection mold | Powder compacting mold | Forging mold | Lenses mold | Glass Lenses mold | ||||

| For Wear & Impact resistant tools , parts | Wear resistance |

--- | AV106 | ○ | ○ | ○ | ||||||||

| --- | AV207 | ◎ | ◎ | ◎ | ||||||||||

| --- | AV210 | ◎ | ○ | ○ | ○ | |||||||||

| --- | AV212 | ◎ | ○ | ◎ | ◎ | ◎ | ||||||||

| --- | AV215 | ◎ | ○ | ○ | ◎ | |||||||||

| --- | AV320 | ○ | ○ | |||||||||||

| --- | AV325 | ○ | ○ | |||||||||||

| Impact resistance |

--- | AG408 | ◎ | ○ | ||||||||||

| --- | AG410 | ◎ | ○ | ○ | ||||||||||

| --- | AG411 | ◎ | ◎ | ○ | ||||||||||

| --- | AG416 | ◎ | ○ | ◎ | ||||||||||

| Measurement (㎜) | Tolerance |

|---|---|

| 5 or less | ±0.10㎜ |

| over5 bellow 10 | ±0.15㎜ |

| over10 bellow 20 | ±0.20㎜ |

| over20 bellow 30 | ±0.25㎜ |

| over30 bellow 40 | ±0.30㎜ |

| over40 bellow 50 | ±0.35㎜ |

| over50 | ±0.7% |

Please use the above charts only as a guide.

Please contact us for the detail.