Microstructure of Typical Grades

-

AF513

AF513

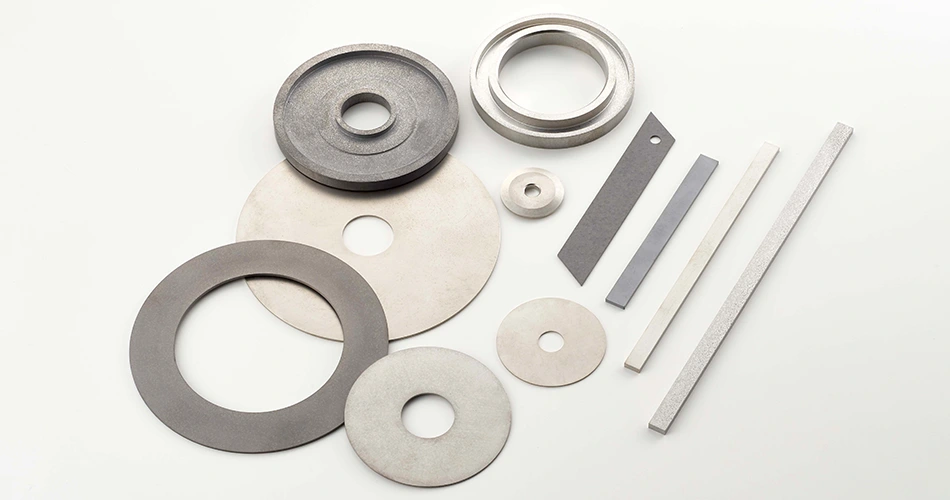

Our blanks deliver excellent edge sharpening performance by balancing both high toughness and high hardness.

The most common grade, AF513, has been used by various customers such as electronic components, resin, automobile parts and rubber.

In addition to the ultra-fine and ultra-fine AF series, we offer K-type and AV212 for metals and the impact-resistant material AG series for specific materials. See Technical details for more information.

For details, please refer to the technical information.

Swipe left or right

to see.

| Application | Class | ISO code |

Grade | Hardness HRA | TRS | |

|---|---|---|---|---|---|---|

| HRA | Hv(GPa) | (GPa) | ||||

| Blanks for Slitters & Blades | K grade | K10 | AF805 | 93.2 | 17.7 | 2.4 |

| K10 | AF906 | 92.4 | 17.3 | 3.4 | ||

| Wear resistance | --- | AV212 | 89.0 | 13.1 | 3.3 | |

| Impact resistance | --- | AG410 | 87.7 | 11.8 | 2.8 | |

| --- | AG411 | 87.0 | 11.2 | 2.8 | ||

| --- | AG416 | 85.5 | 10.2 | 2.7 | ||

| Micro grain | --- | AF505 | 93.6 | 20.1 | 2.0 | |

| --- | AF5085 | 92.7 | 18.0 | 2.6 | ||

| --- | AF513 | 91.4 | 15.6 | 3.3 | ||

| Ultra micro grain | --- | AF308 | 93.6 | 19.4 | 3.8 | |

| --- | AF312 | 92.5 | 17.3 | 4.4 | ||

| High wear resistance | --- | AF303 | 94.2 | 21.0 | 2.9 | |

AF513

AF513

Swipe left or right

to see.

| Application | ||||||

|---|---|---|---|---|---|---|

| Application | Class | ISO code |

Grade | Slitter & Blade | ||

| General cutting | Metal cutting | Crushing | ||||

| Blanks for Slitters & Blades | K grade | K10 | AF805 | ○ | ||

| K10 | AF906 | ◎ | ||||

| Wear resistance | --- | AV212 | ○ | |||

| Impact resistance | --- | AG410 | ○ | |||

| --- | AG411 | ◎ | ||||

| --- | AG416 | ○ | ||||

| Micro fine grain | Micro grain | AF505 | ○ | ○ | ||

| AF5085 | ○ | ○ | ||||

| AF513 | ◎ | ○ | ||||

| Ultra micro grain | AF308 | ○ | ○ | |||

| AF312 | ○ | ○ | ||||

| High wear resistance | AF303 | ○ | ||||

| Measurement (㎜) | Tolerance |

|---|---|

| 5 or less | ±0.10㎜ |

| over5 bellow 10 | ±0.15㎜ |

| over10 bellow 20 | ±0.20㎜ |

| over20 bellow 30 | ±0.25㎜ |

| over30 bellow 40 | ±0.30㎜ |

| over40 bellow 50 | ±0.35㎜ |

| over50 | ±0.7% |

Please use the above charts only as a guide.

Please contact us for the detail.