Grade Properties

Corrosion Resistant Carbide Blanks are available in grades AE2008 and AE809C.

Note for Corrosion resistance: representation of the elution weight of cemented carbide in an acid solution. See technical information for more details.

For details, please refer to the technical information.

Specifications of Grade for Special Type

Application / Grade Recommendations

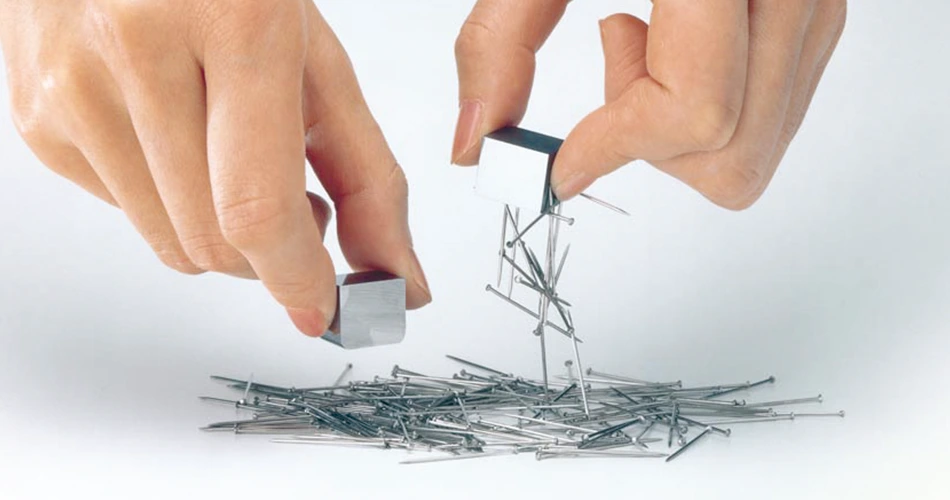

Corrosion Resistant and Non-Magnetic Carbide

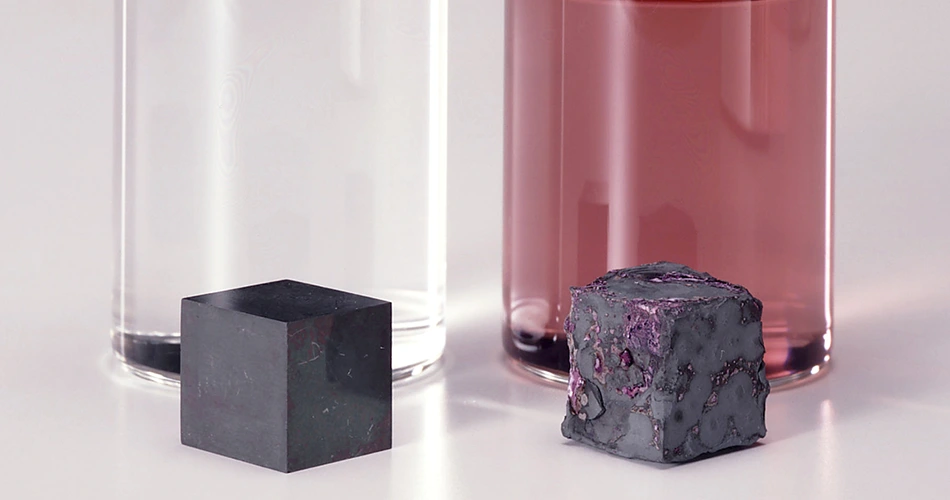

AE2008

Characteristics :

Carbide grade with WC-Ni-Cr demonstrates excellent corrosion resistance and no magnetism.

Application :

Belt cleaner, waste water treatment equipment parts, and magnetic powder molding dies

Corrosion Resistant Carbide

AE809C

Characteristics :

Carbide grade with WC-Co-Ni-Cr achieves excellent corrosion resistance with hardness and toughness

Application :

Belt cleaner, parts for highly corrosive high-pressure plants, and seawater pump parts

Size Availability

| Measurement (㎜) |

Tolerance |

| 5 or less |

±0.10㎜ |

| over5 bellow 10 |

±0.15㎜ |

| over10 bellow 20 |

±0.20㎜ |

| over20 bellow 30 |

±0.25㎜ |

| over30 bellow 40 |

±0.30㎜ |

| over40 bellow 50 |

±0.35㎜ |

| over50 |

±0.7% |

Please use the above charts only as a guide.

Please contact us for the detail.